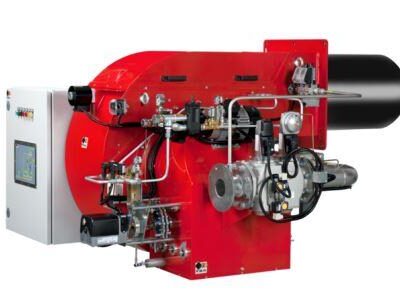

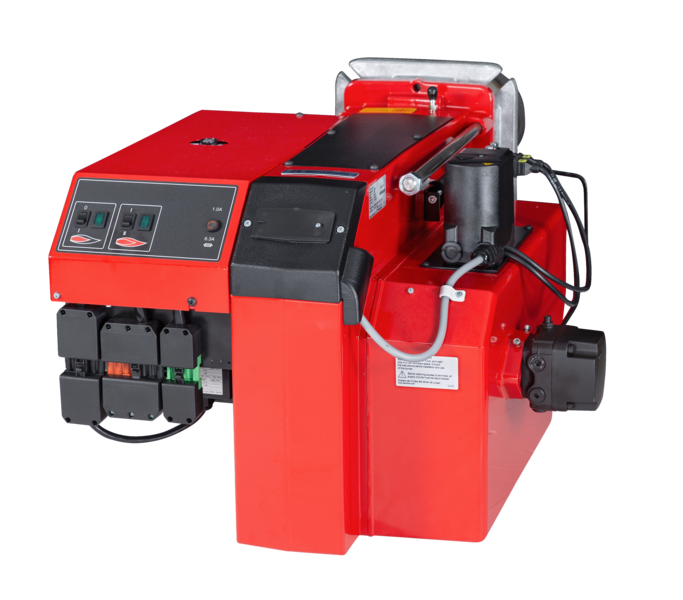

Multi-fuel burners

All over the world our oil burners are known for their reliability, efficiency and performance.

Bentone is leading the way with new development within combustion engineering and we are working continuously to reduce CO2 emissions. We focus on quality, high performance and low fuel consumption and all our burners carry the CE marking and are produced according to the European norm EN 267 and EN 14214 for renewable bio fuels.

Bentone first launched the Multifuel burner for the Scandinavian market in 2013, which is specifically designed for oils with a higher viscosity. The heat exchanger is integrated and also comes with a pump which is designed for corrosive oils and a higher viscosity, Bentones Multifuel burners can handle the most common applications.

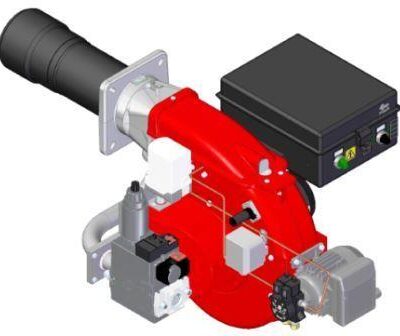

Oil and RME (rapeseed oil) burners

All over the world our oil burners are known for their reliability, efficiency and performance.

Bentone is leading the way with new development within combustion engineering and we are working continuously to reduce CO2 emissions. We focus on quality, high performance and low fuel consumption and all our burners carry the CE marking and are produced according to the European norm EN 267.

We started as a small scale operation with our own developed oil burner and within 10 years we exported our oil burners to major parts of Europe but also to the Middle East. Our success from the start was our high quality and low fuel consumption and we have continued to focus on our winning concept.

Approved burner for industrial applications

In addition our oil burners can be delivered approved according to the EN 267 J and K Directive. (Applicable in the EU and countries that comply with the same standard)

Annex J – Harmonization of the Machinery Directive:

Requirements for installation of burners in industrial applications. For example. ovens, hot air boilers, melting furnaces and spray booths.

EN 746-2 – Industrial process burners:

Requirements for the installation of burners on boilers for processing, refining, industrial ovens, manufacturing and other industrial processes.

Annex K – Harmonization of the Pressure Vessel Directive:

Requirements for the installation of burners on boilers, hot water boilers and hot oil boilers with a temperature above 110 ° C.